|

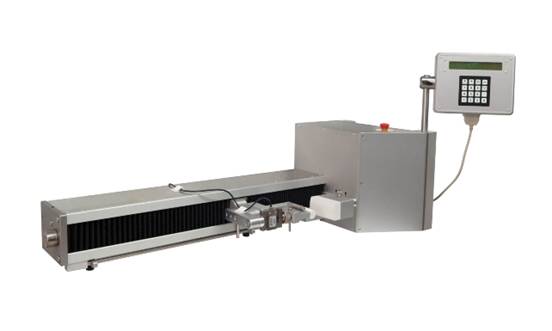

Testmatic System Z3-X500 (TH2730) |

|

|

Is a mechanical test system for testing materials and for tests on materials and products with smaller forces : Force: 3 kN Movement: 500mm This universal machine can be used standalone or with a computer. All measuring data can be transferred by using a serial

standard interface (RS 232) to a PC. for Windows. Typical test materials and products to be tested are

|

Compact affordable and

complete!

|

Ideal for a wide variety of applications...

|

Quality

Control

Also many different types of tests..

Flexible Control

High Precision

|

|

|

|

Description

|

|

Integrated System The system consists of a robust frame, precision control hardware, test software, and channels for load, crosshead position and axial strain. Options include PC, grips, extensometers, and a fourth channel for transverse strain.. Specifications

Load Cell - Standard

|

|

Load Cells - Optional

Options

Minimum PC Requirements · CPU: Pentium Computer · DRAM: 32 Mbytes · 30 MB Hard Disk Space · Monitor: 1024x768 Color VGA · OS: Windows 98, or higher ·

reqires one available serial port RS 232 short delivery times competitive price |

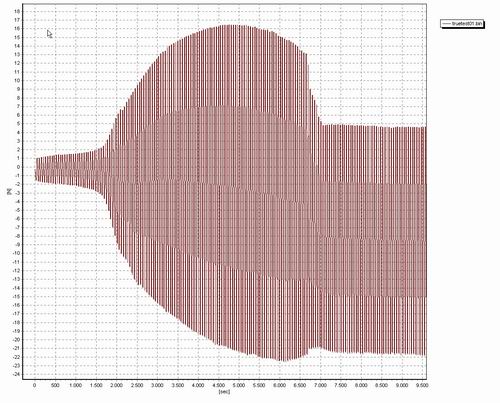

Drawings and pictures of test machine and Windows software

grips

and fixtures

|

Recommended clamps and pressure plates: |

|

|

TH11-5+BP |

|

|

TH 7-5 |

|

|

Th56g+BW universal vice grip with wave jaws |

|

|

Th229+BP small pneumatic Grip head for serial test with pyramid jaws |

|

|

Th23-96St Pressure platens with centric rills |

|

|

|

|

|

|

|

|

we also design special sizes and special function do not hesitate and ask |

www.grip.de |

|

|

|

|

|

|

|

|

|

|

Thümler GmbH |

|

|

Germany 90455 Nürnberg Hans Traut Str. 25 |

Address |

|

|

|

|

+(49) 9122 78711 |

Telephone |

|

+(49) 9122 73127 |

Fax |

|

|

|

Stand

10 Jan 2018